Title:Electric winch hoist LBS grooved main drum for elevator lifting and ship deck.

Product details:

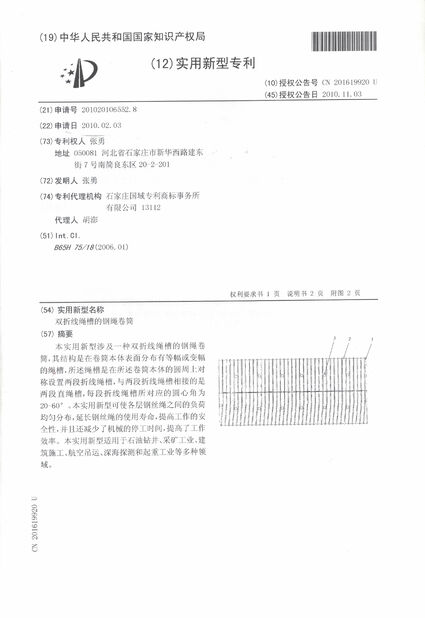

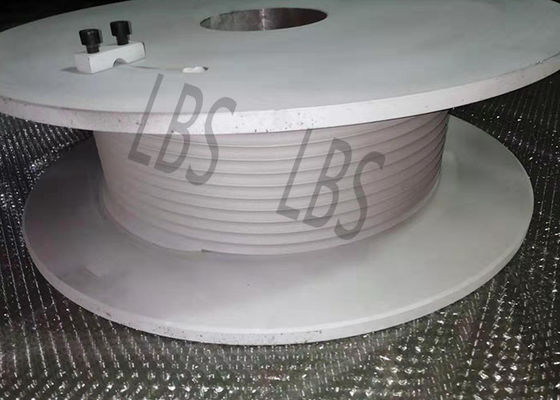

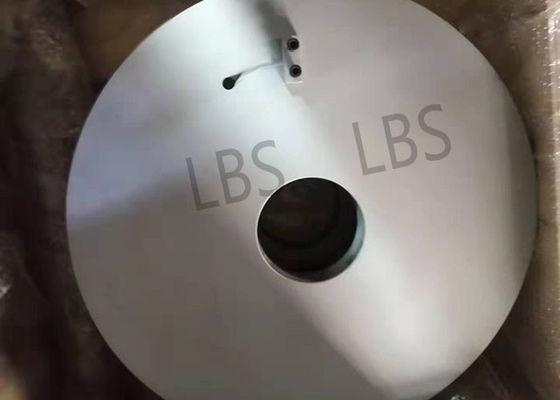

Surface:thermal spray zinc

Drum diameter:225mm

width between the flanges:250mm

groove type:LBS groove

Sling type:steel wire rope

Machine equipment:CNC center

Material: stainless steel / alloy steel/ carbon steel and other high strength steel

This winch drum uses LBS groove,and its special advantages as follows:

1. the structure of groove is based on the rope's diameter and structure so that it can make the rope crushed against groove wall in the spooling.

In that case,each layer will be neat and well-organized.

2.Prolong rope's service life and recude the cost.

Service condition of LBS groove:

1.The flanges of drum must be perpendicular to drum wall at any condition,even under load.

2.The rope must be kept under tension in the process of spooling so that the rope can be crushed against groove wall. when the spooling can not meet this condition,a press roller shall be used.It is generally recommended that the tension of the rope shoule be at least 2% breaking tension or 10% working load.

3.The fleet angle range should generally never be more than 1.5 degrees and not less than 0.25 degrees.

4.When the wire rope released from the drum goes around the sheave,the center of sheave should be over the center of drum.

5. The rope structure must be kept roiund and not loose,even under the maximum load.

6.The rope must be anti-rotation structure.

7. Pls measure the change of rope diameter under different load.

Product application range:

It can be widely used on aviation,shipping,offshore crane industry,oil field,coal,port,marine platform,construction,railwayand other heavy machinery field.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!