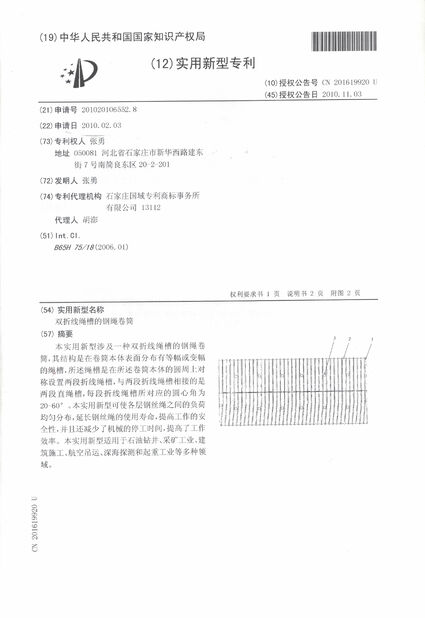

Product Description:

LBS Sleeve - Winch Drum Cover, Drum Sleeve Protector

The LBS Sleeve is designed to provide an effective and reliable solution for lifting and discharging steel wire ropes. It is an ideal choice for drum protection and to prevent wire rope from abrasion and fatigue. The LBS Sleeve is available in both left and right entry direction, and can be customised in size and thickness according to your requirements. It is manufactured with high-quality materials including alloy steel and polymer nylon, providing enhanced durability. The sleeve is also designed with regular thickness to guarantee maximum protection for your wire ropes. With its robust construction and reliable performance, the LBS Sleeve is your perfect choice for winch drum cover and drum sleeve protection.

Applications:

LBS Sleeve is a grooved sleeves protection device for pipes, designed and manufactured by LBS. The product model number is LBSS-Series, and it is widely certified by international standards such ISO9001, CE and CCS. It is made from high-quality materials with a minimum order quantity of one. It is light weight and wear-resistant. The price of LBS Sleeve depends on the customization and it can be negotiated. It is exported in standard wooden cases or pallets. The delivery time is 15-30 days and the payment terms are T/T or L/C. The production facility is a CNC Center and it has a supply ability of 100. The size, color and thickness of the product can be customized. The processing method is machining operation.

| Number | Rope Diameter(mm) | Rotation Direction | Drum Diameter(mm) | Drum Length(mm) | Application |

| 1 | 13 | Left | 430 | 763 | Oil Workover Rig And Oil Truck Drum |

| 2 | 18 | Left | 623 | 1144 | Oil Workover Rig And Oil Truck Drum |

| 3 | 22 26 | Left or Right | 730 | 1120 | Drilling Rig |

| 4 | 18 22 32 | Left or Right | 670 | 1240 | Windlass |

| 5 | 28 32 36 | Left or Right | 560 | 630 | Construction Machinery Rotary Drilling Rigs And Cranes |

| 6 | 26 45 | Left or Right | 760 1146 | 1970 1765 | Ocean Cranes, Docks |

| ... | | | | | |

Customization:

| Product Basic Parameters(Specific specifications can be customized according to requirements) |

| Product Name | Grooved Sleeves | Type Specification | LBSS-202310004 |

| Brand | LBS | Producing Area | Shijiazhuang, Hebei, China |

| Production Facility | CNC Center | Certification | ISO9001 |

| Function | Lifting and discharging of steel wire ropes | Quality Assurance | 1 year |

| Color | Customized | MOQ | 1 pcs |

| Material | Alloy steel (Customized) | Processing Method | Machining operation |

| Rope Groove Type | Lebus or spiral | Rope Capacity | 10-10000m |

| Rope Type | 3-200mm | Power Source | Electric motor / Hydraulic motor |

| Rope Entry Direction | Left or right | Accessory Products | Lifting structure |

| Applicable Equipment | Winch drum, smooth drum | Weight | 200kg |

| Specific specifications can be discussed. Welcome to the news consultation! |

Support and Services:

LBS Sleeve offers technical support and services to ensure that customers have a problem-free experience with our product. We provide comprehensive support and assistance to our customers through our knowledgeable customer service team, online resources, and technical support staff.

Our customer service team is available to answer any questions or concerns you may have. We strive to provide timely and accurate responses to our customers in order to ensure the best possible experience.

We also offer online resources to help customers with any technical issues they may encounter. These resources include user guides, FAQs, and tutorials to ensure our customers are getting the most out of their LBS Sleeve products.

Finally, our technical support staff is available to provide assistance with any technical issues our customers may face. The staff is knowledgeable and experienced in troubleshooting and resolving any issues related to our products.

At LBS Sleeve, we strive to provide our customers with the best possible experience. Our technical support and services are designed to help our customers get the most out of their LBS Sleeve products.

Packing and Shipping:

Packaging and Shipping for LBS Sleeve:

LBS Sleeve will be packaged in a sealed box for shipping. The box will include the sleeve, a user guide, and any additional accessories. The box will be securely sealed, and the shipment will be tracked.

The shipment will be sent via a reliable courier service. Delivery will take 2-3 business days depending on the destination.

FAQ:

- Q1: What is the Brand Name of the product?

- A1: The Brand Name of the product is LBS.

- Q2: What is the Model Number of the product?

- A2: The Model Number of the product is LBSS-Series.

- Q3: Where is the Place of Origin of the product?

- A3: The Place of Origin of the product is Shijiazhuang, Hebei, China.

- Q4: What is the Certification of the product?

- A4: The Certification of the product is ISO9001, CE, CCS.

- Q5: What is the Minimum Order Quantity of the product?

- A5: The Minimum Order Quantity of the product is 1.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!