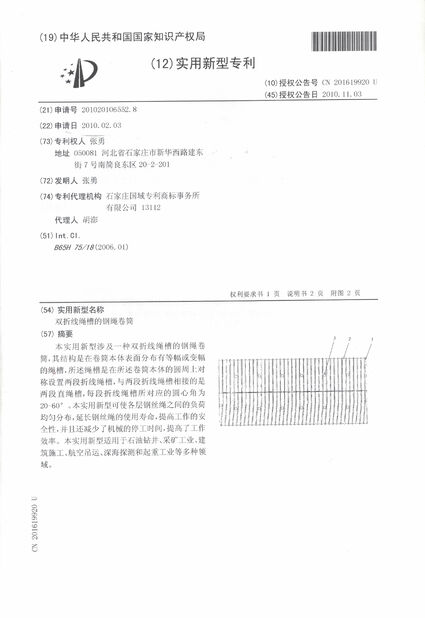

Product Description:

The Lebus Sleeve is available in a regular thickness, making it a great option for most winch drums. Its installation mode is also versatile, allowing it to be either welded or bolted onto your winch drum with ease. This flexibility ensures that the Lebus Sleeve can fit a wide range of winch drum sizes and configurations.

One of the key benefits of the Lebus Sleeve is Lebus groove can arrange the rope regularly, ensuring that the wire rope is wound in multiple layers without tangling, avoiding the wire rope from being damaged due to squeezing, and avoiding the work stoppage due to tangling of the wire rope during the winding process, which greatly increases the life of the wire rope, improves work efficiency, and saves wire rope expenses

The Lebus Sleeve is also ideal for those who want to keep their winch drum looking its best. The sleek design of the Lebus Sleeve gives your winch drum a professional and polished appearance, which is perfect for those who use their winch drum for business or commercial purposes.

In conclusion, the Lebus Sleeve is a top-quality accessory that every winch drum owner should have. Its precision-engineered design, versatile installation mode, and protective capabilities make it an excellent investment for anyone who wants to prolong the lifespan of their winch drum. Whether you use your winch drum for personal or commercial purposes, the Lebus Sleeve is a product that you can rely on to keep your winch drum in top condition.

Applications:

The LBS Sleeve is designed to fit a variety of winch drums, thanks to its customizable size. The grooved sleeves are specifically designed to ensure a smooth and efficient lifting and discharging of steel wire ropes. The LBS Sleeve is a perfect fit for a range of applications, including offshore drilling, marine winching, and other heavy-duty lifting operations. The product is also suitable for use in the construction and mining industries, where heavy loads need to be lifted and discharged.

The LBS Sleeve is a versatile product that can be used in a variety of scenarios. For example, it can be used in the oil and gas industry to lift and discharge drilling equipment. The product is also suitable for use in the marine industry, where it can be used to lift and discharge heavy-duty equipment such as anchors and buoys. The LBS Sleeve is also ideal for use in the construction industry, where it can be used to lift and discharge heavy construction materials such as steel beams and concrete blocks.

The LBS Sleeve is a high-quality product that is built to last. It comes with a minimum order quantity of one and is available at a negotiable price. The product is delivered in export standard wooden cases or pallets and has a delivery time of 15-30 days. Payment terms are flexible and can be made through T/T or L/C. The product has a supply ability of 100 and is available for customization to meet your specific needs. With the LBS Sleeve, you can be assured of efficient lifting and discharging of steel wire ropes in any scenario.

Customization:

Support and Services:

The LBS Sleeve product technical support and services include:

- Assistance with installation and setup

- Troubleshooting for any issues that may arise

- Guidance on product maintenance and care

- Access to software updates and upgrades

- Product training and user manuals

- Warranty and repair services

Packing and Shipping:

Product Packaging:

The LBS Sleeve will be packaged in a sturdy cardboard box, lined with bubble wrap to ensure safe transport. The product will be placed in a clear plastic bag to protect it from any moisture during shipping. The box will be sealed with packing tape and labeled with the customer's shipping address and tracking number.

Shipping:

The LBS Sleeve will be shipped via standard ground shipping through a reputable carrier such as UPS or FedEx. Shipping times may vary based on the customer's location, but typically take 3-5 business days. The customer will receive a confirmation email with a tracking number once the order has been shipped.

FAQ:

Q: What is the brand name of the product?

A: The brand name of the product is LBS.

Q: What is the model number of the product?

A: The model number of the product is LBSS-Series.

Q: Where is the product manufactured?

A: The product is manufactured in Shijiazhuang, Hebei, China.

Q: What certifications does the product have?

A: The product is certified with ISO9001, CE, CCS.

Q: What is the minimum order quantity?

A: The minimum order quantity is 1.

Q: What is the price of the product?

A: The price of the product is negotiable.

Q: What are the packaging details for the product?

A: The packaging details for the product are export standard wooden case or pallet.

Q: What is the delivery time for the product?

A: The delivery time for the product is 15-30 days.

Q: What are the payment terms for the product?

A: The payment terms for the product are T/T, L/C.

Q: What is the supply ability for the product?

A: The supply ability for the product is 100.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!